The term Traceability is formed by Trace and Ability. Traceability is the ability to track any food, feed, food-producing animal or substance that will be used for consumption through all stages of production, processing and distribution. In the event of a food incident it enables the identification and subsequent withdrawal or recall of unsafe food from the market. If the food has not reached the consumer, a trade withdrawal is undertaken. If the food has reached the consumer, a product recall is undertaken which includes notification of the consumer through in-store notices and press releases.

Traceability and product recall are important as they enable food businesses to respond quickly to food safety/quality incidents thereby ensuring that consumer exposure to the affected product is prevented or minimised. A good traceability system ensures that withdrawals/recalls are limited to implicated products, thereby minimising disruption to trade and company finances.

Legal requirements, International Standards and Private Voluntary Standards

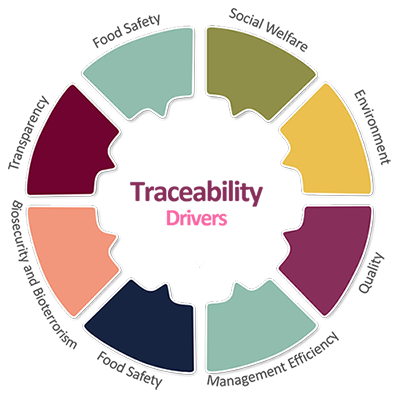

For the competent authorities the implementation and use of robust and effective traceability systems in the food chain can contribute to a number of aims, for example:

There are also clear benefits for industry to be gained from such systems, for example:

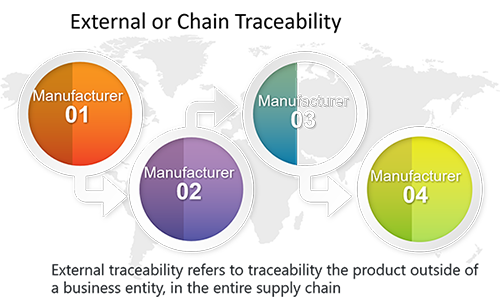

Traceability information that is external and internal to a food business operation is given in the attached diagram.

Espiga Exports has the experience in traceability implementation tailored to your needs, it could be covering all the levels of Traceability or just some of them depending your needs and resources.

Espiga Exports has the experience in Traceability implementation tailored to your needs, it could be covering all the levels of Traceability or just some of them depending your needs and resources.

We are ready to exceed your expectations and help you achieve your goals.